Automatic Liquid Bottling Equipment Bottle Cap Machine Small Bottle Filler Glass Vials Filling and Sealing Pharmaceutical Medicine Bottle Liquid Filling Machine

Package size per unit product 230.00cm * 85.00cm * 150.00cm Gross weight per unit product 750.000kg Product Description

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | PYG |

| Automatic Grade | Fully Automatic |

| Material Type | Liquid |

| Filling Valve Head | Multi-Head |

| Feed Cylinder Structure | Multi-Room Feeding |

| Dosing Device | Rotor |

| Filling Principle | Pressure |

| Packaging Container Lifting Structure | Bottle Filling Machine |

| Structure | Rotary |

| Packaging | Bottle |

| Packaging Material | Glass/Plastic |

| Item | Bottle Capping Machine |

| Option Filling Volume | Below 500ml |

| Power Supply | 220/380V |

| Power Consumption | 0.75 Kw |

| Weight | 650 Kg |

| Overall Dimension(L*W*H) | 2440 X 780 X 1600 (mm) |

| Transport Package | Export Standard Wooden Case |

| Specification | CE, GMP, SGS, BV |

| Trademark | LTPM |

| Origin | China |

| Production Capacity | 25sets/Mouth |

Packaging & Delivery

Package size per unit product 230.00cm * 85.00cm * 150.00cm Gross weight per unit product 750.000kgProduct Description

Product Description

1.Application:

Oral liquid, liquid, pesticide, perfume, cosmetics and pulp food category, etc.

2. Features:

A. Controlled by PLC, the frequency convesion in finitely variable speeds.

B. All6 processes from spreading roll, AMP bottle forming, filling, sealing the dne, printing serial numbers, cutting the end, cutting apart, controlled by programming.

C. The computer human interface has simple and clear operation.

D. The filling head doesn't drop, leak, rideing bubbled and spill over.

E. All are made of high-qualited stainless steel, according with the standard GMP.

F. Mostly pneumatic components and wirings adopt inward fittins.

G. Automatic and mechanical botting, precise calculation and limited deflectiom.

3. Technical Parameters:

Max forming depth | 12mm |

| cutting frequency | 0-25 times |

| acking material packaging | PET/PE PVC/PE(0.2-0.4)×120mm |

| capacity | 1-50ml |

| indtalled power | 4.5kw |

| voltage | 220v-380v/50hz |

| wholemachine's weight | 750kg |

| dimension | 2300x850x1500(mm) |

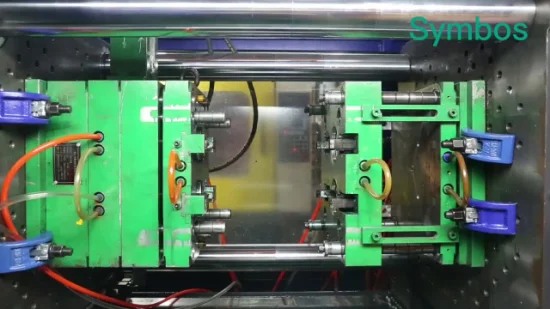

Machine product

LTPM China is considered one of the major Pharmaceutical Machinery Supplier and exporter in China mainland. Professional, Enthusiasm, Service and Team Work has been always our value to create for our Staff and customers. As year 2012 we position our value as "A Pharma Machinery Division, For A Better Life", creating a Win-Win Platform for our clients and staff for a better life is our vision.

Packing & ShippingAll machine delivery with anti rust spray, film wrapping and Sea shipping affordable wooden box.FAQ

Q1: How many different sealing type of cartoner?

A: Mainly two different types: Glue Sealing and Folding sealing. Q2: What kind of product can cartoner machine pack?

A: Blister strip, Soft Alu Strip, Glass Bottle, Plastic Bottle, Soap, Bulb,etc. any kinds of product which can be packed into small box under our machine range. Q3: How many different models we have?

A: we have different models according to different production capacity which are 50box/min, 100boxes/min, 200boxes/min, 300boxes/min, 400boxes/min Q4: Can the cartoner machine connected with different inner packaging machinery?

A: Yes, the cartoner machine can connect to filling machine, blister packing machine, pillow type packing machine, tube filling machine, etc. Q5: What is the maintainance period of cartoner machine?

A: Every three month the operator should do the lubrication and system checking on the mechanical system andelectrical system. According to our Maintanance Manual, the operator can do it easily. Q6: Do you have manual or operation video for us to know more about the machine?

A: Yes, not only manual or operation video, 3D drawing also available to make as per yourdesign,also the video we can make of testing the material from our packaging machine if your packing goods easier for us to find from our local market. Q7: How can I trust you for the first time business ?

A: if you don't trust us, then we can use Alibaba trade assurance service, guarantee your money, and guarantee your machine's on-time delivery and machine quality. Q8: Is engineer available to serve oversea?

A: Yes, but the travel fee is paid by you. So actually to save your cost, we will send you a video of full details machine installation and assist you till the end. Q9: How can we make sure about the machine quality after we put the order?

A: Before delivery, we will run the machine for half an hour - 1 hour to ensure that the machine is OK. And we will sendyou the pictures and videos for you to check the quality, and also you can arrange for quality checking by yourself or by your contacts in China.

Second, We have six Technicians get Passport ready to travel around the world to adjust the machine for our customers.

Related Products

-

![Professional Manufacturer Fully-Automatic Bonnell Spring Mattress Machine]()

Professional Manufacturer Fully-Automatic Bonnell Spring Mattress Machine

-

![High-Speed Plastic Bottle Cap Compression Molding Machine]()

High-Speed Plastic Bottle Cap Compression Molding Machine

-

![Fully-New Full Automatic Liquid Complete Pet Bottle Pure Drinking Mineral Water Washing Filling Capping 3in1 Monoblock Filling Packing Machine]()

Fully-New Full Automatic Liquid Complete Pet Bottle Pure Drinking Mineral Water Washing Filling Capping 3in1 Monoblock Filling Packing Machine

-

![Single Head 15 Needles China Flat Cap T-Shirt Hat Embroidery Machine Computerized Embroidery Machine]()

Single Head 15 Needles China Flat Cap T-Shirt Hat Embroidery Machine Computerized Embroidery Machine