Mineral Water Bottle Cap Vacuum Compression Molding Cap Machine

Overview mineral water bottle cap vacuum compression molding cap machine Product Description Machine Features: 1) Precis

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | ST-850SElll |

| Clamping Way | Hydraulic |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE |

| Product Name | Injection Molding Machine |

| Model No. | St-850seiii |

| Certificate | CE/ISO9001/SGS |

| Color | Customized |

| Clamping Force(Kn) | 850 Ton |

| Production Capacity(Sets) | 1000 |

| After Sales Service | Engineers Available to Service Machinery Oversea |

| Function | for Plastic Parts Production |

| Advantage | Energy Saving,Long Service Life |

| Stable Performance | Short Cycle Time |

| Feature | Stable Quality, Competitive Cost, Careful Service |

| Service | One-Stop Complete Solution |

| Operation Language | Multilingual, You Can Choose |

| Quality | Professional Quality Control Team |

| Weight(Ton) | 43 |

| Transport Package | Woolen Case |

| Trademark | SINOTECH |

| Origin | Made in China |

| HS Code | 8477101090 |

| Production Capacity | 50-600PCS/Hr |

Product Description

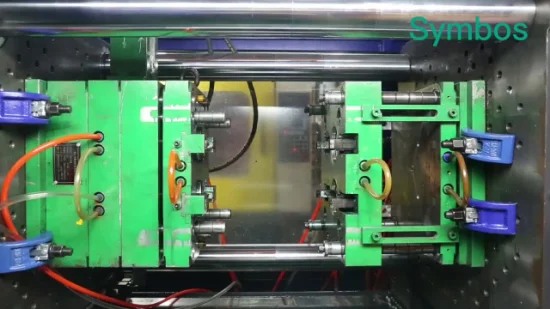

mineral water bottle cap vacuum compression molding cap machine

Product Description

Machine Features:

1) Precision hydraulic synchronous template adjusting system

2) Optimal design of high-strength precision clamping structure, Clamping unit rigidity and accuracy

3) Large colorful screen high-precision computer system, precision control, easily operation, multi operation language available. High-precision displacement sensor system, temperature control accuracy, big capacity data storage and date protection ability

4) World famous brand electrical system

5) Balanced type of double injection cylinder, eliminate oblique torque, diminishes deformation of screw and barrel, extend life of screw and barrel, optimizes plasticizing effect. Machine injection under multi-pressure and at various speed, with big capacity hydraulic motor.

6) Large torque oil motor

7) Highly abrasion resistant alloy sliding block

8) The integrate type oil detachable oil tank, magnetic filter and bypass strainer. Reasonable and highly efficient lubrication system. Modularized energy conservation high response oil system

9) Highly precise transducer, multi-stage control of opening stroke, speed and position. Flexible tie bars nut eliminate fatigue fracture, assure tie bars long working life.

10) Security door fitted with hydraulic, mechanical and electrical interlocking triple safety device, fully protect machine operator.

11) Energy saving system, no extra energy consumption due to output volume changes according to load alteration. During stage of holding pressure, servo motor lower down energy consumption, 0 energy consumption during machine cooling stage, save 20%-80% energy consumption compare with standard machine.

We are professional plastic injection molding machine manufacturer for all kinds of plastic products, Clamping force from 50 to 4000Ton, injection weight from 50 to 10000g. Also we have CE and ISO certification.

Product Parameters| Item | Unit | 850SElll | ||

| Screw diameter | mm | 90 | 100 | 110 |

| Theoretical shot volume | cc | 2990 | 3691 | 4467 |

| Shot weight (PS) | g | 2691 | 3322 | 4020 |

| Shot weight (PS) | oz | 95 | 117 | 142 |

| Length/Diameter ratio | L/D | 22.6 | 20.0 | 18.0 |

| Injection pressure | MPa | 212 | 171 | 142 |

| Injection rate | cm³/sec | 572 | 706 | 854 |

| Plasticizing capacity(PS) | G/s | 73 | 90 | 121 |

| Injection stroke | mm | 470 | ||

| Max. Screw speed | rpm | 124 | ||

| Injection unit force | Ton | 19.8 | ||

| Carriage stroke | mm | 600 | ||

| Clamping force | Ton | 850 | ||

| Max. daylight | mm | 2200 | ||

| Clamping stroke | mm | 1025 | ||

| Distance btwn. Tie bars | mm | 1060*1060 | ||

| Min mould dimension | mm | 740*7040 | ||

| Mould thickness range | mm | 450-1100 | ||

| Ejector force | Ton | 25 | ||

| Ejector stroke | mm | 350 | ||

| No. of ejector pins | unit | 21 | ||

| Max. motor power | kW | 83.8 | ||

| System pressure | MPa | 17 | ||

| Hydraulic pump capacity | L/min | 440 | ||

| No. of heater zones | unit | 5+1 | ||

| Heater input power | kW | 50 | ||

| Ultimate capacity | kw | 132.8 | ||

| Current | A | 161.4 | ||

| Net weight | Ton | 43.0 | ||

| Oil filling capacity | L | 1500 | ||

Company ProfileFAQ

1. who are we?

We are based in Jiangsu, China, start from 2011,sell to North America(30.00%),South America(20.00%),Western Europe(16.00%),Oceania(10.00%),Mid East(10.00%),Eastern Europe(5.00%),Southeast Asia(5.00%),Africa(4.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Extrusion Blow Molding Machine,Pet Blow Molding Machine,IBC Cage Production Line,Plastic Extrusion Line,Waste Plastic Recycling And Pelletizing Line

4. why should you buy from us not from other suppliers?

Our company have the strict system from the material purchase,machine part processing and inspect. We have the detailed Assemble prcess according to the machine Assemble structure. We test not one time before the machine delivery to the customer factory.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

Related Products

-

![16cavity Pco1810 Pco1881neck Size 28mm Plastic Pet Preform Mold Bottle Pet Preform Mold]()

16cavity Pco1810 Pco1881neck Size 28mm Plastic Pet Preform Mold Bottle Pet Preform Mold

-

![Qt5-15 Fully Automatic Hydraulic Compressed Solid Color Paver Paving Interlocking Building Curbstone Cinder Hollow Cement Concrete Brick Block Making Machine]()

Qt5-15 Fully Automatic Hydraulic Compressed Solid Color Paver Paving Interlocking Building Curbstone Cinder Hollow Cement Concrete Brick Block Making Machine

-

![Pet Preform Manual Hand Feeding Blow Molding Machine Positioning Bottle Square Jar Automatic Plastic Making Machine Manufacturer]()

Pet Preform Manual Hand Feeding Blow Molding Machine Positioning Bottle Square Jar Automatic Plastic Making Machine Manufacturer

-

![Integrated Fully Automatic Pallet Stretch Wrapping Machine]()

Integrated Fully Automatic Pallet Stretch Wrapping Machine