Hot Runner Water Bottle Preform Mould Multi Cavity Pet Preform Mould for Plastic Injection Machine

LIPENG MACHINERY MOULD CO.,LTD is located in "China mold town - Huangyan, Zhejiang, land, sea and air transportation is

Send your inquiryDESCRIPTION

Basic Info

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | CE, ISO |

| Standard | DME |

| Customized | Customized |

| Transport Package | Wooden Case |

| Trademark | LIPENG |

| Origin | China |

| HS Code | 84790090 |

| Production Capacity | 500sets/Year |

Product Description

LIPENG MACHINERY MOULD CO.,LTD is located in "China mold town - Huangyan, Zhejiang, land, sea and air transportation is convenient.The factory has 20 years of mold development, experience in the design, mold design and manufacture of professional manufacturers. The use of advanced CAD / CAM / CAE software system is strong, production equipment, including Computer three-dimensional measuring instrument, small, medium and large machining centers, high-speed carved, CNC lathes, CNC wire cutting, EDM and all kinds of general-purpose equipment, greatly shortening the duration of mold manufacturing, mold.

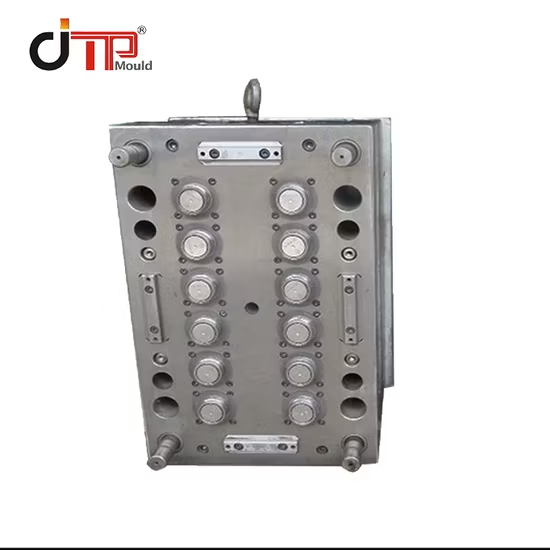

LIPENG MOULD specialized in manufacturing PET Preform Moulds (PET Preform Molds) injection molding system, consists of technologists with rich experience, and senior engineers with master's degree and professional in 3D. We invite many technical committee members and senior professors in mould line are as the technical consultants for our company.YUMING always focuses on its innovation and development. Various kinds of processing equipment and detection measurement instrument are imported, as well as special drawing soft is applied in designing performs, samples and manufacturing testing mold. We supply special technology training and other good after-sales service.After ten years effort, it has grown steadily and turned into a Professional PET preform mold supplier .Product Desciption1. Needle Valve of No-Cutting PET Preform Moulds2. The number of PET preform mould cavities is up to 72 cavities for standard neck finishes, such as PCO1881, PCO1810, and 30. The cam roller design for the thread splits helps operator maintenance freely.3. Individual Valve-Gate unit with balanced hot runner system.4. The PET preform moulds use Dual Tapers design for Lock5. Maintenance free Roller Cams, make both the opening and closing actions on the thread splits; The bearing has less frication, makes sure the movement of the thread split plate smoothly, and ensures the longer working lift. This roller cam system guarantees the longer service time of the PET prefrom moulds.6. PET preform mould materials: Mould cavity, core, neck: Germany 2316Valve pin: SKD51 from JapanMould other plate: P20 and 45# Mould Data

| NO.of cavity | 12cav. | 16cav. | 24cav. | 32cav. | 48cav. | 72cav. |

| 18g(cm) | 62*38*43 | 79*38*43 | 88*46*45 | 86*68*48 | 105*68*55 | 110*78*58 |

| Weight(kg) | 630 | 810 | 1150 | 1750 | 2450 | 3100 |

| 28g(cm) | 62*38*45 | 79*38*45 | 88*46*48 | 86*68*52 | 105*68*58 | 110*78*62 |

| Weight(kg) | 660 | 850 | 1250 | 1900 | 2600 | |

| 40g(cm) | 62*38*48 | 79*38*48 | 88*46*50 | 86*68*55 | 105*68*62 | 110*78*65 |

| Weight(kg) | 690 | 890 | 1350 | 2000 | 2750 | 3000 |

Mould making step :

| 1.R&D | We support customer R&D. Make the files or improve the design if you needed. |

| ↓ | |

| 2.Negotiation | the quality, price, material, delivery time, payment item, ect. |

| ↓ | |

| 3.Place an order | according your own design or you chooses our design. |

| ↓ | |

| 4. Mould | According customers request to build the mould. Before make the mould, we send mould design to customer approval first, before move forward to production; we send samples to customer to confirm first. |

| ↓ | |

| 5. Sample shoot | If the first sample come out is not satisfied customer, we modify the mould and until meet customers satisfactory. |

| ↓ | |

| 6.Products in store | If your quantity is beyond our storage, we will provide lead time to you. |

| ↓ | |

| 7. Delivery time | Delivery goods by sea or by air, according customers |

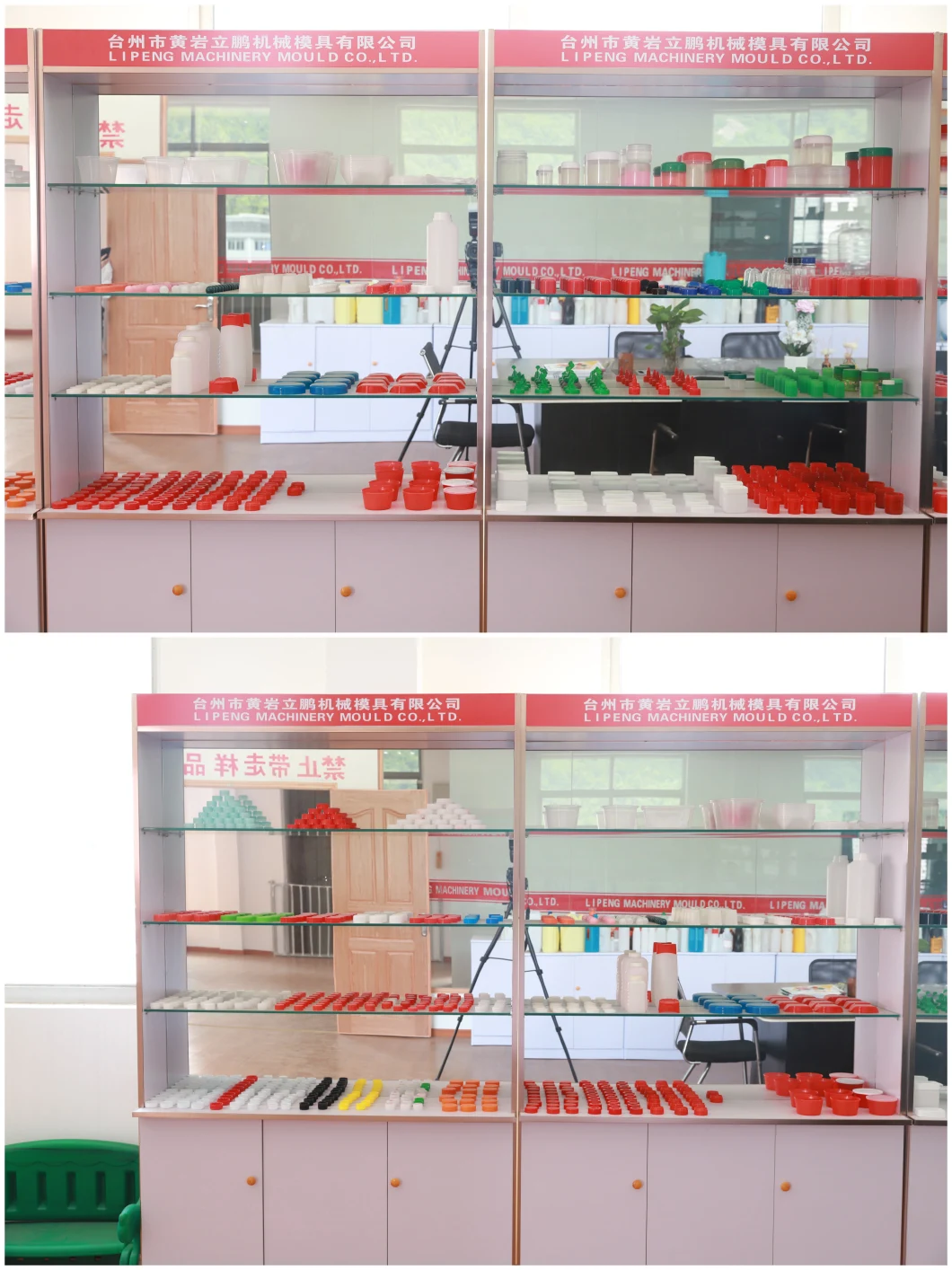

Samples rooms

Working Office

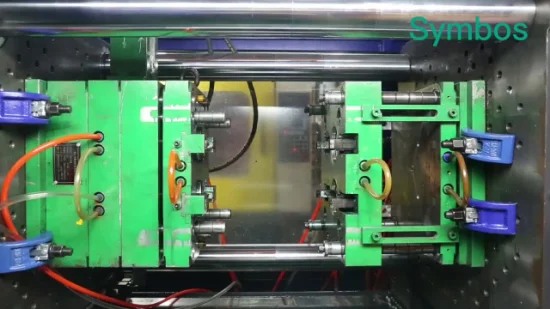

Working shop

Mould packing and shipping

Related Products

-

![Mini Rice Machine 10tpd-500tpd Fully Automatic Paddy Rice Machine Parboiled Rice Mill Machine Rice Milling Machine]()

Mini Rice Machine 10tpd-500tpd Fully Automatic Paddy Rice Machine Parboiled Rice Mill Machine Rice Milling Machine

-

![OEM Multi Cavities 4 Cavities Plastic Injection 5 Gallon Bottle Cap Mould]()

OEM Multi Cavities 4 Cavities Plastic Injection 5 Gallon Bottle Cap Mould

-

![Cost-Effective Plastic Injeciton Mould Mold Molds for Auto Parts Water Bottle Cap Supplement Jar Lid Soap Hose Battery]()

Cost-Effective Plastic Injeciton Mould Mold Molds for Auto Parts Water Bottle Cap Supplement Jar Lid Soap Hose Battery

-

![Automatic Flip Top Cap Closing Machine Lid Closure Compression Machine]()

Automatic Flip Top Cap Closing Machine Lid Closure Compression Machine