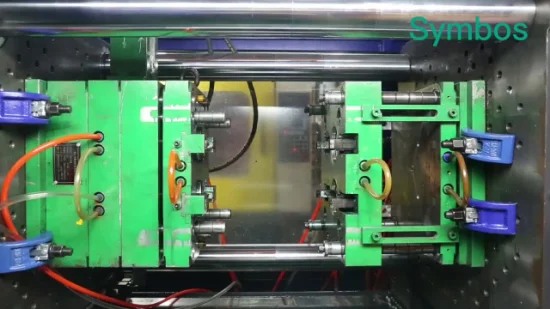

Factory Price 20mm 28mm 46mm 5 Gallon Plastic PP Flip Top Screw Water Pet Bottle Cap Jar Cover Closure Lids Mold Mould Manufacture

About US We are a professional plastic mold and plastic machine manufacturer, with the strength of manufactured with goo

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | cap mold |

| Runner | Hot Runner |

| Design Software | UG |

| Installation | Fixed |

| After-sales Service | After Sale Service |

| Transport Package | Wooden Box |

| Specification | 28PCO, 3025, 38 |

| Trademark | BLOWELL |

| Origin | China Taizhou Cap Mould |

Product Description

About US

We are a professional plastic mold and plastic machine manufacturer, with the strength of manufactured with good quality and pretty competitive price.

We can make various kinds of Mould for each customer as per their requirements.

The quotation can be made based on drawings or samples provided by the customers.

Our products are both excellent in quality and reasonable in price.

Your satisfaction is guarantee.

Engineering capabilities include:

1.Parts design

2.R&D products

3.Prototype design and production assembly

4.Reputable design software used for all design work

5.Fast automatice remould design

6.Mould design with a team of experienced specialists

Product Description

we can supply: bottle cap mould, mineral water cap mould, beverage cap mould, cap mould for 3 gallon or 5 gallon bottle, tamperproof cap mould, child resistant cap mould, flip top cap mould, disc top cap mould, shampoo cap mould, different kinds of edible oil cap mould, engine oil cap mould, jerry can cap mould, sport cap mould, cosmetics cap mould, wine cap mould, toothpaste cap mould, aerosol cap mould, candy cap mould, jar cap mould, eye drop cap mould, cap mould with different diameters, hot runner cap mould, cold runner cap mould, motor release cap mould, knock-off release cap mould, cap mould with 1-96 cavities, etc.MOLD PACKAGE

FAQ

Q. When can I get the price ? A. We usually quote within 24 hours after we got your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority. Q. How can I get the accurate price ? A.There are some basic specs we need to know for price calculate, that are: 3D drawings in STP,IGS,X-T format are avaialble, Please suggest us your quantity too. Q. Do you accept the OEM? A. OEM is welcome. We can custom the good according to your design. Q. What is the shipping ?

A:By express(FedEx, UPS, DHL, TNT, EMS, etc...),By Air,by shipping. Q. How do i pay for the order? A.The common payments are T/T(Telegraphic Transfer),western union , Q. I have an idea for a new product, but don't know if it can be manufactured. Can you help?A. Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs. Q. What are the advantages to having my parts manufactured locally?A. We can offer quick reaction times to any changes in specification, batch size or material. Q. My components have already been developed on CAD. Can you use the drawings?A. Yes! DWG, DXF, IGES, Solidworks and Rhino files can all be used to generate quotes, models and mould tools - this can save time and money in producing your parts. Q. Can I test my idea/component before committing to mould tool manufacture?A. Yes, we can use CAD drawings to make models for design and functional evaluations. Q. What type of plastic is best for my design/component?A. Materials selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternatives and suggest the best material. Q. What type of mould tool do I need?A. Mould tools can be either single impression (one part at a time) or multi-impression (2,4, 8 or 16 parts at a time). Single impression tools are generally used for small quantities, up to 10,000 parts per year whereas multi-impression tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you. Q.Ok, I've decided to go ahead with my project. How long will it take to get my parts?A. It can take 3-16 weeks to have the mould tool manufactured depending on the part's complexity and the number of impressions (single or multi).

Related Products

-

![Customized Plastic Pet Bottles Preform Jar Injection Mould Packaging Molding Mold]()

Customized Plastic Pet Bottles Preform Jar Injection Mould Packaging Molding Mold

-

![Multi Head Computerized Automatic Embroidery Machine Cap T-Shirt Hat Hoodie Shoe Flat Monogram Single Multi Head High Speed Embroidery Machine]()

Multi Head Computerized Automatic Embroidery Machine Cap T-Shirt Hat Hoodie Shoe Flat Monogram Single Multi Head High Speed Embroidery Machine

-

![Customer Design Plastic Injection Mould for Electronic Parts/Car Parts/Motor Parts/Food Package/Plastic Bottle]()

Customer Design Plastic Injection Mould for Electronic Parts/Car Parts/Motor Parts/Food Package/Plastic Bottle

-

![2019 Zhejiang Hongzhan Hot Sale High Quality Semi-Automatic Sealing and Shrinking Packing Machine]()

2019 Zhejiang Hongzhan Hot Sale High Quality Semi-Automatic Sealing and Shrinking Packing Machine