Automatic Plastic Cap Lid Bottle Cover Liner Cutting Punching and Inserting Machine for Coil Die Cutting

Liner Cutting and inserting machine 1. Scope of Application: This machine is widely used in the industry of Bottle Cap,

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | FRTB-SD2-B |

| Automation | Automatic |

| Computerized | PLC |

| Labor Needed | 1 Worker |

| Production Rate | 100-120PCS/Min |

| Work Station | Single/Double |

| Cap Specification | 20-80mm |

| Voltage | 220/380V |

| Total Power | 4kw |

| Dimension | 2000×1000×1500mm |

| Operation Panel | Touch Screen |

| After-Sale Service | Engineers Available to Service Machinery Overseas |

| Liner Material | PE/Foam Foil/Paper Board/Aluminum |

| Machine Type | Liner Cutting and Inserting |

| Guarantee | 1 Year |

| Transport Package | Wooden Box |

| Specification | Stainless steel |

| Trademark | FURI |

| Origin | China |

| HS Code | 8422303090 |

| Production Capacity | 10PCS/Mon |

Product Description

Liner Cutting and inserting machine

1. Scope of Application:

This machine is widely used in the industry of Bottle Cap, Liner, Medicine, Foodstuff, Household Chmeicals, Package, etc. It is an ideal inserting machine.

2. Features:

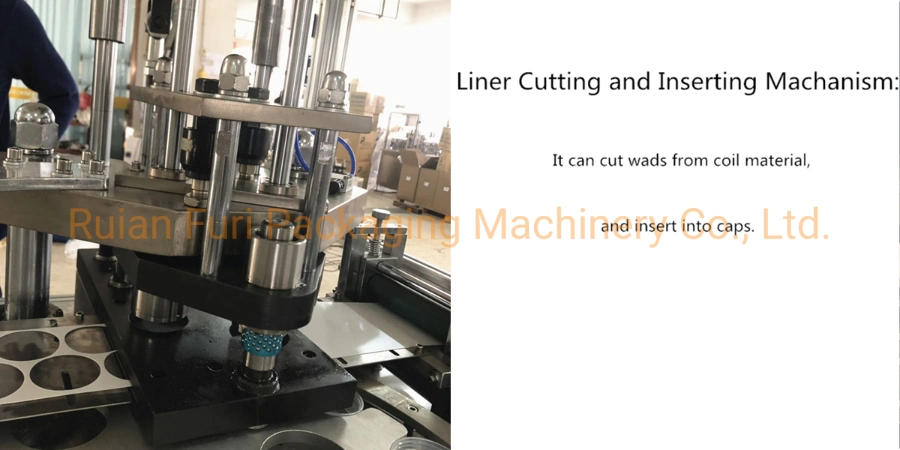

Cap Lining Machine is for inserting the liner/ wad into the plastic caps. Punching and inserting the liner at the same timeProduction Flow Chart: Arrange cap, delivering cap, liner cutting and inserting, delivering cap1) This machine replaces the handwork. It automatically inserts the liner into the bottle cap, and can raise work efficiency greatly.2) Reasonable Liner Sealing, Fast speed, High efficiency, Safe and Sanitary product.3) This machine is specially suitable for the occasion which has strict and severe sanitary requirements. It can avoid secondary pollution on the materials, and thus it can omit the sterilizing technics.4) Arrange Cap System attaches the function of cap elimination, in order to make sure every finished bottle cap upward.5) It has automatic counter inside, and can raise the working efficiency afterwards.6) The materials of liner is roll, and the cutting and inserting are in process at one time, which can raise the working efficiency.7) It adopts mechanical drive deliver position machanism to make the machine work smoothly. It is suitable for various kinds of bottle caps and aluminum foil or PE foam.8) It adopts PLC controller, and has the alarm while out of liner and bottle cap. The electric control system adopts frequency conversion techniques. It has the advantages of free setting, wide pplication, easy operation, stable working, convenient cleaning and maintenance, durable in use, etc.9) Our fully automatic packing machine is in strict accordance with National GMP Standard and process requirements.

3. Structure of equipment:

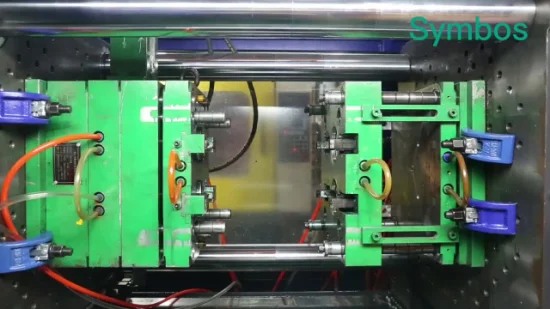

1) Automatic cap sorting machanism: It puts the messy bottle caps in order, and makes all caps upwards.2) Bottle cap delivering machanism: It delivers the ready bottle cap into the liner inserting machanism in order and correct way.3) Liner cutting machanism: It puts the roll stock liner into cutting.4) Liner inserting machanism: It inserts the liner to the cap to finish liner inserting procedure.

4. Technical Parameters:

| Cap Specification | Productivity | Voltage | Power | Dimension L× W× H | N. W. |

| 20-40/40-80mm | 160-200bottles/min. | 380 V | 4 KW | 2000× 1000× 1500(mm) | 600KGS |

OUR COMPANY

MACHINE PACKAGING

More Details , Kindly contact us.Attn:Becky Pan Location: (ZHIXIN INDUSTRIAL ZONE)C-13-12, NO.66, TINGCHAO RD., SHANGWANG STREET, RUIAN, WENZHOU, ZHEJIANG, CHINABy Flight: Arrive at Wenzhou AirportBy Train: Arrive at Ruian StationWe customize all kinds of non-standard bottle cap processing auto solutions.

Related Products

-

![Aopack Fully Automatic Box Maker Corrugated Cardboard Carton Box Making Machine]()

Aopack Fully Automatic Box Maker Corrugated Cardboard Carton Box Making Machine

-

![Pet Preform Blowing Full Fully Automatic Oil Water Bottle Making Stretch Blow Molding Moulding Machines]()

Pet Preform Blowing Full Fully Automatic Oil Water Bottle Making Stretch Blow Molding Moulding Machines

-

![Semi Automatic Aerosol Hair Spray Snow Spray Aerosol Gas Filling Equipment Spray Paint Production Line Butane Gas Refilling Machine]()

Semi Automatic Aerosol Hair Spray Snow Spray Aerosol Gas Filling Equipment Spray Paint Production Line Butane Gas Refilling Machine

-

![Servo Automatic Stretch Water Pet Jar Plastic Bottle Blow Blowing Blower Molding Molder Moulding Making Machine Tank Machinery Manufacturers Price Equipments]()

Servo Automatic Stretch Water Pet Jar Plastic Bottle Blow Blowing Blower Molding Molder Moulding Making Machine Tank Machinery Manufacturers Price Equipments